History

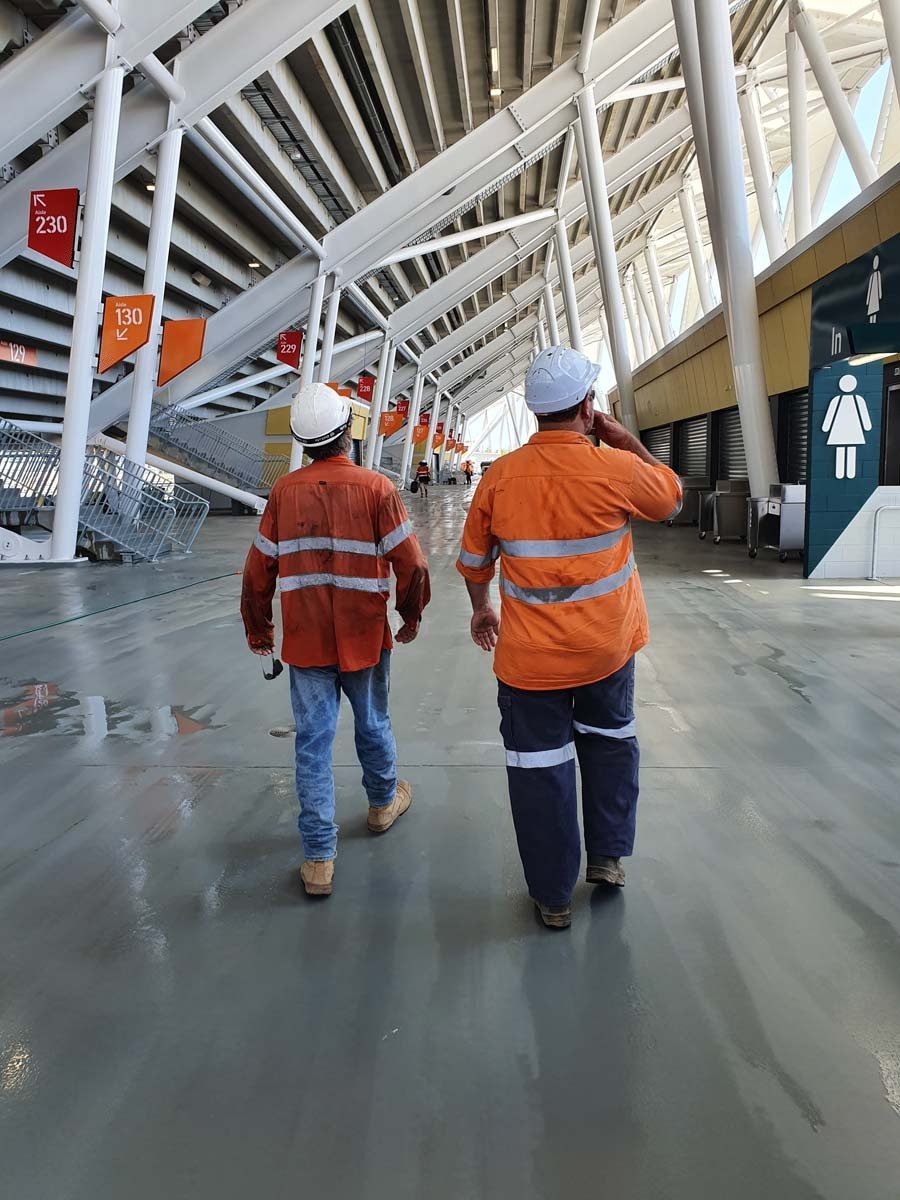

Since 1990, we have been a family-owned and operated business committed to providing quality blasting and painting services to clients throughout the North Queensland region. Our first and foremost commitment is to our local community—utilising the local workforce and participating in major community projects.

As our operations continued, so did our expansion into new business avenues, transforming us into a multi-faceted blasting company today. We now supply a full range of services, including UHP water jetting, vacuum loading and extensive on-site services, in addition to our original scope of abrasive blasting and protective coatings.

Our Staff

Over the years, we have built a stable and skilled workforce with many long-term permanent employees. We promote leadership culture, loyalty, and commitment to values throughout our workforce, from labourers to top-tier management ensuring employee retention.

Our business is an EEO employer; we are proud of our diverse workforce comprising five different nationalities and ten ESL staff. Our ability to connect and welcome workers into our team has provided opportunities to those in the local community and skilled workers overseas.

Family-Owned Business

Safety

WABS is committed to encouraging a culture of cooperation, initiative, and responsibility to maintain a safe and healthy workplace for all employees and clients. We promote a culture where harm to our people or the environment through work is unacceptable; at no time will production pressures take priority over this. At WABS, we recognise our moral and legal responsibilities to provide a safe working environment for our employees.

Our objectives are met with a continual improvement system integrated into the Safety Management System, ensuring all work practices comply with legislative duties and industry standards. To achieve this commitment, WABS, in conjunction with its employees, aims to identify, control and preferably eliminate health and safety hazards and their associated risks. We do this by integrating risk management principles, training and safe work systems into our operations.

Quality

We are committed to operating our business in a manner that consistently meets and exceeds industry standards and the quality expectations set by our clients. These expectations include terms of response, operational capability and cost-effectiveness. To achieve these objectives:

We regularly engage our staff in personal and professional development opportunities

Build strong client and supplier relationships

Seek out feedback (positive or negative) to identify actions for the continual improvement of our operations

Environment

WABS is committed to protecting our environment by approaching its activities with an environmentally responsible attitude and managing any risk that may negatively impact the ecosystem. As a company, we recognise that our work activities may at times result in risks that lead to adverse environmental outcomes. Our priority is to manage any environmental risks and adverse effects on fauna, flora, and local communities. We aim to achieve this by promoting a strong environmental ethic as part of our culture, analysing and identifying activities that may constitute a risk and implementing relevant control measures.

30+ Years of Experience

Our Facilities

Our vast land size, substantial painting and blasting facilities, as well as advanced equipment, means no job is too small or too big for our team to handle. If you’re worried about the weather impacting your work, we’ve got you covered.

The specially designed 2000sqm paint shed features an overhead crane, a dedicated steel-shot blast room with running rail tracks, and most importantly, four filtered extraction fans to eliminate hazardous fumes and regulate humidity.

Weather Monitoring Station

A weather monitoring station is set up at the front of the site office and inside our shed to ensure that climate conditions are correct for coating applications.

Our site also features an additional dedicated paint shed with monorail tracks and hooks designed explicitly for handrails and guards.

Additional Facilities

Our facilities attached to our main paint shed includes a 400sqm garnet room (with an additional 20m opening) that allows for all-year-round blasting with the modern dust recycling system. An extra 220sqm covered blast bay and bunded blast bay perfect for awkward and oversized items exists on the second block of our land. Accompanying the abrasive blasting bays is the dedicated water-jetting bay connected to a holding sump with an oil-water separator and an eco-friendly dewatering system.

Our Fleet

- 10t Linmac tractor crane

- 5 forklifts – 14t Hyster, 12t Komatsu, 2 x 5t Hysters, 1 x 4.5 Toyota

- 1 truck mobile mounted abrasive blasting unit

- 3 water-jet units – 2 mobile truck-mounted (2 ultra-high-pressure units and 1 high-pressure unit)

- 2 hot metal spray units

- Plural component reactor and 20KVA generator (for poly linings)

- Air assisted, airless and electric airless pumps (for spraying various ratios and volume solid paint)

- Compressors – 2 x airman compressors, 1 x Compair trailer-mounted 400cfm, 1 x atlas Copco trailer-mounted 330cfm, 1 x Compair 1000cfm

- Also available are various sizes of blast pots with holding capacities of 50kgs up to 2t of garnet

- 2 x KingVac vacuum loading trucks

If you’re looking for a reliable, well-equipped and environmentally conscious company for abrasive blasting and surface protection, look no further than us.